Robotics Laboratory (RobLab)

Project Description

Over the last decades robots have become more and more essential companions. Regardless of challenging, risky environments, robot systems are working with heavy loads, high speed and enormous accuracy, especially where humans hit their limits. For example, robots support workers at drilling and milling where extreme high accuracy is required. Furthermore, robots support welding and assembly tasks in the automotive industry under high work load. However, usually robot systems are highly adapted to their tasks and mostly just following predetermined movement patterns. Normally, robot are moving with high speed and under enormous forces on precalculated paths, no matter if obstacles or humans are crossing their way. To avoid collisions the workspaces are entirely separated, especially from human operators, by surrounding cages including safety systems. This requires a lot of space, is very expensive and almost eliminates a dynamic Human-Machine-Interaction.

Robotic systems are becoming more and more relevant for medical applications, such as remote controlled surgery or robotic radiotherapy systems. The afore mentioned Human-Machine-Interaction became a major key part but generally requires new safety concepts as well as new path planning algorithms and in some cases a completely new robot kinematic design. Therefore, some of the state-of-the-art robotic systems, like the KUKA iiwa, provide force and torque sensors and thus can detect collisions with obstacles or humans within crucial reaction times. These robots nowadays fulfil novel ISO safety standards for Human-Machine-Interactions and constitute the new era of harmless robots.

In general, the RobLab workgroup develops methods and software tools to model, control, analyse and simulate innovative, new robotic systems and its motion planning. Especially, we are developing software and concepts for articulated arm systems.

Dynamische Arbeitsraumanalyse für verschiedene Robotergeometrien

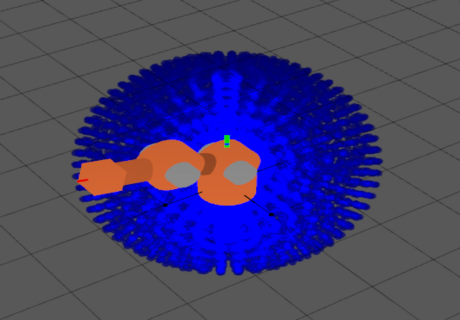

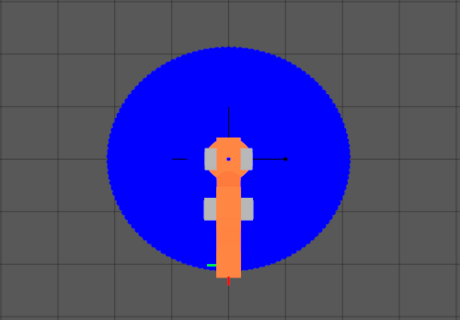

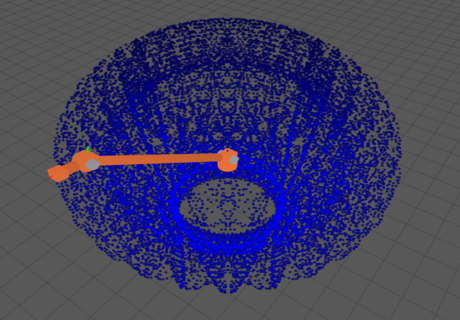

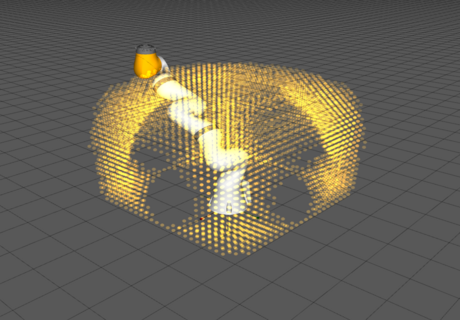

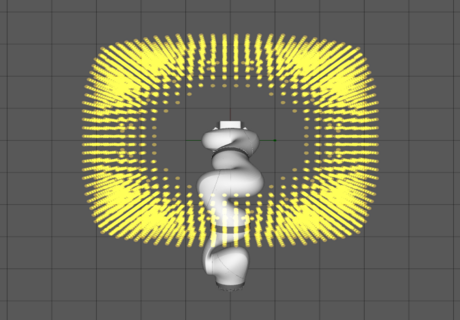

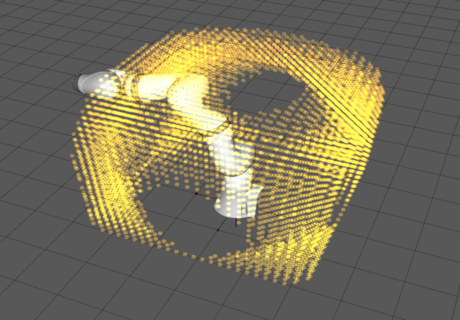

We are focusing on software which enables professional construction, developing, and simulating of existing robotic systems as well as experimental concept designs. We apply methods to analyse various different kinematics with regard to their dexterity, working and configuration spaces. However, small changes in robot configurations mostly results in large changes in their kinematic chain and thus in their workspace. By implementing real time computation we qualify the user to identify all changes in a direct way.

Designing new robot systems is a massive and time consuming task. Especially, the planning of the interaction of several robots or the human-robot-interaction is challenging. Our system is able to reduce the development time and as a consequence the development costs. Furthermore, the possibility to visualize changes in the kinematics and its influences on the robot’s behaviour in real time may provide a better understanding of the system and its design. This aspect can be very useful in teaching and training students or experts.